- Sales hotline

+86-512-62653308

No.6 Qingqiu Street, Industrial Park,

Suzhou, Jiangsu Province, China.

Laser power:

Laser power:

Processing width:

Processing width:

Dimension:

Dimension:

Cutting material and thickness:

Cutting material and thickness:

Line width:

Line width:

Maximum scribing depth:

Maximum scribing depth:

Repetitive positioning accuracy:

Repetitive positioning accuracy:

laser power:6000W-20000W

laser power:6000W-20000W

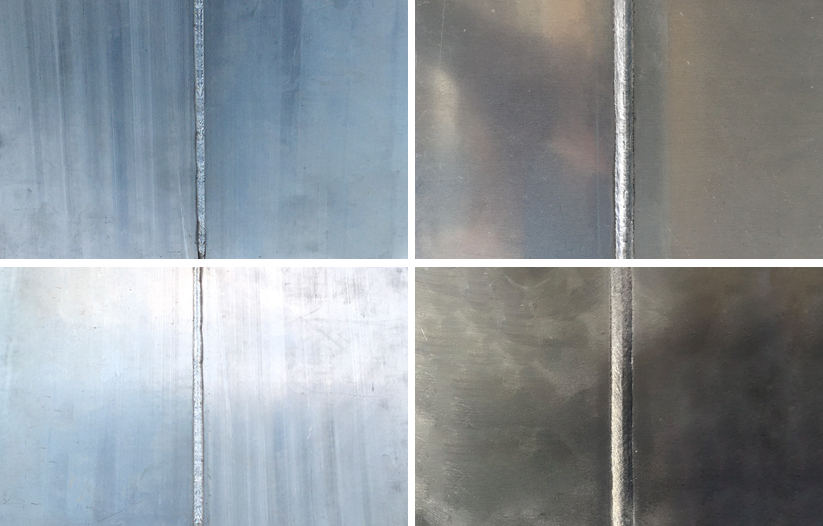

Weldable materials: high strength steel, aluminum alloy, titanium alloy and other metal materials

Weldable materials: high strength steel, aluminum alloy, titanium alloy and other metal materials

Customization: strong customization ability to provide customers with system solutions

Customization: strong customization ability to provide customers with system solutions

Suitable industries: rail transit, military industry, shipbuilding, scientific research institutions and other industries

Suitable industries: rail transit, military industry, shipbuilding, scientific research institutions and other industries

Inquire Now >

Inquire Now >

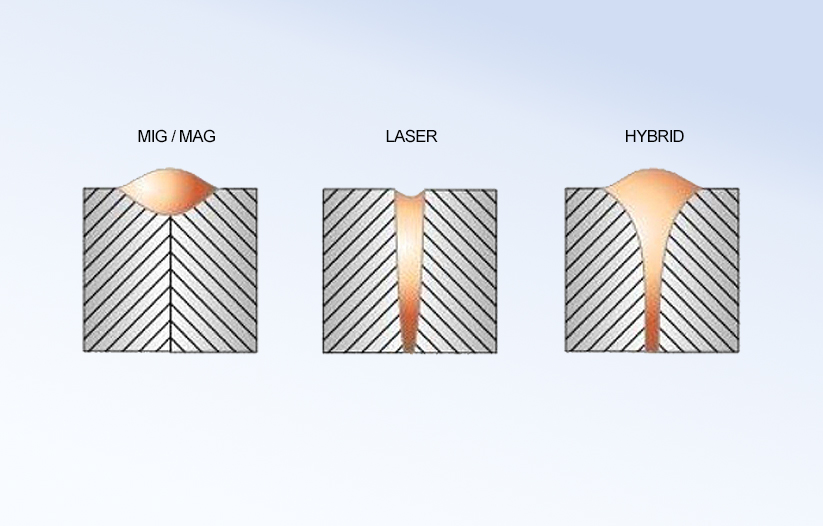

Laser-MIG Hybrid Welding Machines—FDW Series Characteristic parameter

| Equipment model | QL-FDW6000 | QL-FDW8000 | QL-FDW10000 | QL-FDW15000 | QL-FDW20000 |

| laser power | 60000W | 8000W | 10000W | 15000W | 20000W |

| Laser wavelength | 1070nm | ||||

| Arc welding machine | Fronius/Lincoln | ||||

| Weld form | Butt joint, Corner joint and other conventional joint forms | ||||

| Power demand | 380V/50Hz | ||||

| Cooling mode | Water cooling | ||||

| Other requirements | The aluminum alloy welding wire should select the front push-pull mechanism. + wire feeder | ||||

*All technical parameters shall be subject to the latest technical scheme.