- Sales hotline

+86-512-62653308

No.6 Qingqiu Street, Industrial Park,

Suzhou, Jiangsu Province, China.

High Power Fiber Laser Cutting Machines-F Series

Ultra-high Power Fiber Laser Cutting Machines—G Series

Low and Medium Power Fiber Laser Cutting Machines—A/D Series

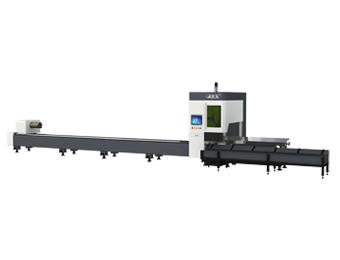

Standard Laser Tube Cutting Machines—AK Series

Standard Laser Tube Cutting Machines—AC Series

Handheld Laser Welding Machines—HFW Series

Laser Cleaning Machines—CL Series