- Sales hotline

+86-512-62653308

No.6 Qingqiu Street, Industrial Park,

Suzhou, Jiangsu Province, China.

Laser power:

Laser power:

Processing width:

Processing width:

Dimension:

Dimension:

Cutting material and thickness:

Cutting material and thickness:

Line width:

Line width:

Maximum scribing depth:

Maximum scribing depth:

Repetitive positioning accuracy:

Repetitive positioning accuracy:

Sheet thickness range:1mm~16mm

Sheet thickness range:1mm~16mm

working area:3000mm*1500mm~12000mm*2500mm

working area:3000mm*1500mm~12000mm*2500mm

Apparent size: determined according to the layout

Apparent size: determined according to the layout

Maximum number of extended cutters supported:≤4platform

Maximum number of extended cutters supported:≤4platform

Inquire Now >

Inquire Now >

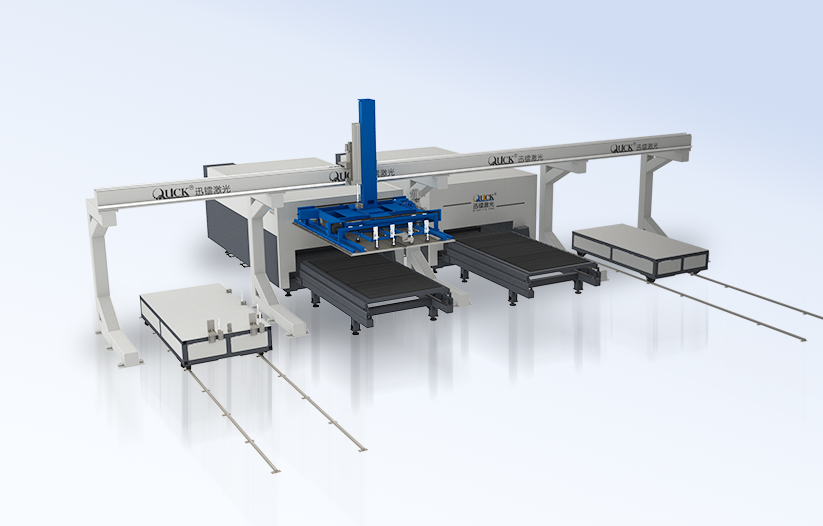

Gantry structure, stable operation, suitable for loading and unloading of plates of moderate thickness;

Modular design can realize the connection of multiple laser cutting machines such as one driven two and one driven three;

Automatic sheet splitting and thickness measurement function to ensure reliable feeding and no wrong cutting.

Intelligent automatic sorting system can be selected to improve intelligence;

The intelligent sorting system can replace the manual sorting after cutting, accurately classify and stack at the same time, and reduce the labor intensity of workers;

Modular design, can be customized with multiple models.

Modular optional modules such as multi machine parallel, material warehouse system and intelligent sorting system;

Cooperate with the material warehouse system to realize rapid switching of small batch and multi variety;

With ATS central control system, it can realize all-weather unattended, and can seamlessly connect MES / ERP and other upper software.

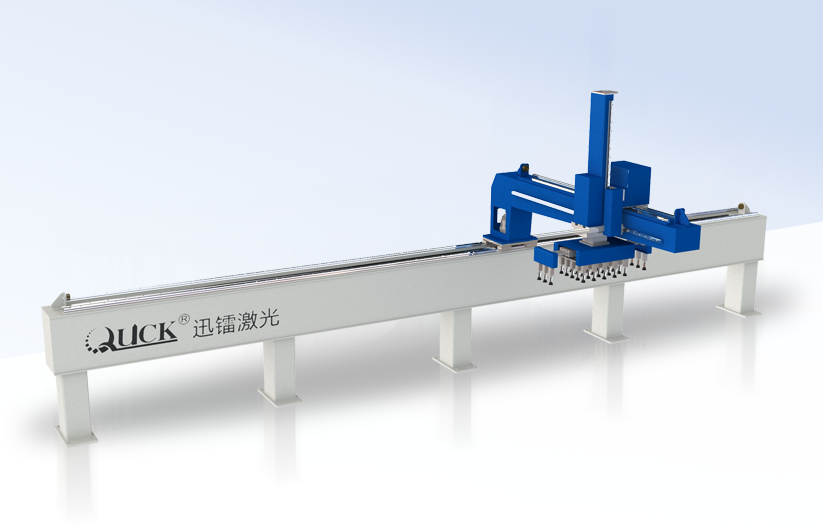

Cantilever automatic loading and unloading system

Compact space, smaller floor area and more diverse layout;

It is suitable for loading and unloading of conventional sheet metal.

Automatic Loading & Unloading Systems of Sheet Cutting—ATR Series Characteristic parameter

| type | name | Parametric | Unit element |

| Cantilever loading and unloading | Optional format | 3015 | |

| Minimum feeding thickness | 1 | mm | |

| Maximum feeding thickness | 6 | mm | |

| Maximum feeding weight | 220 | Kg | |

| Maximum matching number | 4 | ||

| X-axis stroke | It depends on the number of cutting machines | ||

| Z-axis stroke | 1000 | mm | |

| X-axis speed | 25 | m/min | |

| Z-axis speed | 20 | m/min | |

| Gantry loading and unloading | Optional format | 3015/4020/6020 | |

| Minimum feeding thickness | 1 | mm | |

| Maximum feeding thickness | 12/8/6 | mm | |

| Maximum feeding weight | 500/500/600 | Kg | |

| Maximum matching number | 4 | ||

| X-axis stroke | It depends on the number of cutting machines | ||

| Z-axis stroke | 1000 | mm | |

| X-axis speed | 25 | m/min | |

| Z-axis speed | 20 | m/min | |

| Automatic sorting system | Optional format | 3015/4020/6020 | |

| Minimum sort size | 100*100 | mm | |

| Maximum sorting size | 1000*1000 | mm | |

| Maximum sort size | 4 | mm | |

| X-axis stroke | 3000/4000/6000 | mm | |

| Y-axis stroke | 1500/2000/2000 | mm | |

| Z-axis stroke | 1000 | mm | |

| X-axis speed | 30 | m/min | |

| Y-axis speed | 30 | m/min | |

| Z-axis speed | 25 | m/min | |

*All technical parameters shall be subject to the latest technical scheme。