- Sales hotline

+86-512-62653308

No.6 Qingqiu Street, Industrial Park,

Suzhou, Jiangsu Province, China.

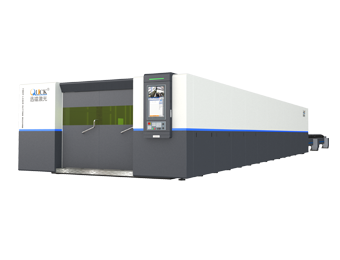

High Power Fiber Laser Cutting Machines—F Series

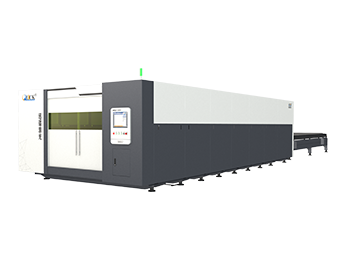

Ultra-high Power Fiber Laser Cutting Machines—G Series

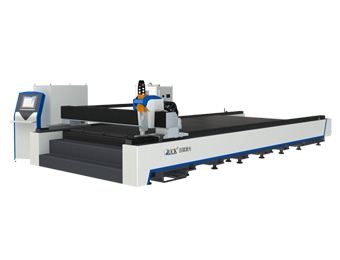

Low and Medium Power Fiber Laser Cutting Machines—A/D Series

Large Format Fiber Laser Cutting Machines—H Series

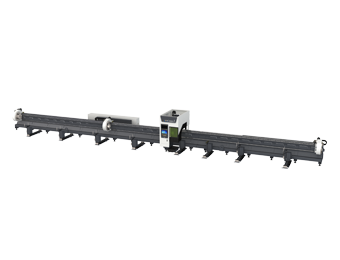

Zero-tailing Heavy-duty Laser Tube Cutting Machines—34BK Series

Three-chuck Laser Tube Cutting Machines—25BK Series